디에스글로벌

주요설비

앞으로도 풍부한 경험을 가진 최고의 엔지니어들과 함께 끊임없는 연구를 통해 기술의 혁신을 이루어 갈 것이며,

고객의 미래가치를 높이고, 지속가능한 파트너 가 될 수 있도록 노력하겠습니다.

Manufacturing Facilities

Test Equipments

Manufacturing Facilities

MCT

MCT

CNC

Lathe

Milling machine

Radial drilling machine

| NO | DESCRIPTION | MODEL | CAPACITY | Q’ty |

|---|---|---|---|---|

| 1 | Machining center | Hyundai-wia KG-800 | 1400 x 1050 x 1200 | 1 |

| 2 | Machining center | Hitachi HC-500 | 500 x 700 x 750 | 1 |

| 3 | Machining center | Mazak H-630 | 1050 x 850 x 850 | 1 |

| 4 | Boring Machine | Doosan infracore 130T | 3000 x 2000 x 800 | 1 |

| 5 | Boring Machine | Daewoo DBC-130S | 2000 x 1500 x 900 | 1 |

| 6 | Boring Machine | Toshiba BTD-11E | 2000 x 1600 x 600 | 1 |

| 7 | Turning machine | OM TM2-25N | Ø2500 | 1 |

| 8 | CNC | Toshiba TMD13 | Ø1200 | 2 |

| 9 | CNC | Doosan PUMA VT900M | Ø900 | 1 |

| 10 | CNC | Doosan PUMA V550A | Ø740 | 1 |

| 11 | CNC | Doosan VT1620M | Ø2000 | 1 |

| 12 | Radial drilling machine | Nambug 1600 | 1600mm | 1 |

| 13 | Milling machine | Namsung NSM-9100 | 800mm | 1 |

| 14 | Milling machine | Hwacheon HMV-1300 | 800mm | 1 |

| 15 | Lathe | Hwacheon HL580-1500 | Ø600 | 1 |

| 16 | Lathe | TONG-IL TIPL-4 | Ø1060 | 1 |

| 17 | Compressor | – | 200L | 1 |

| 18 | Crane | – | Max. 20ton | 1 |

| 19 | Crane | – | Max. 10ton | 1 |

| 20 | Crane | – | Max. 5ton | 1 |

| 21 | Crane | – | Max. 3ton | 1 |

| 22 | Crane | – | Max. 2.5ton | 1 |

| 23 | Crane | – | Max. 1ton | 1 |

| 24 | Shot Blast Machine | WRH-2025 | 3000 x 3500 | 1 |

| 25 | Painting booth | – | 200m2 | 1 |

Test Equipments

Hydraulic Test M/C

Ultrasonic Thickness Gauge

P/Thickness Gauge

Surface Roughness tester

Portable PMI

Helium Leak Detector

| NO | DESCRIPTION | MODEL | CAPACITY | Q’ty |

|---|---|---|---|---|

| 1 | Hydraulic Test M/C (400㎏f/㎠) | Sungwoo | 50A ~ 300A | 1 |

| 2 | Hydraulic Test M/C (158㎏f/㎠) | Sungwoo | 300A ~ 600A | 1 |

| 3 | Hydraulic Test M/C (110㎏f/㎠) | Sungwoo | 400A ~ 1000A | 1 |

| 4 | Pressure Gauge | WIZE | 0.5MPa ~ 100MPa | 15 |

| 5 | Torque Wrench | TOHNICH | 196N·m ~ 2100N·m | 3 |

| 6 | Vernier calipers | Mitutoyo | 150mm ~ 2000mm | 6 |

| 7 | In/Outside Micrometer | Mitutoyo | 200mm ~ 1000mm | 4 |

| 8 | Height Gauge | Mitutoyo | 150mm ~ 600mm | 4 |

| 9 | Depth Gauge | Mitutoyo | 0~200mm | 1 |

| 10 | Ultrasonic Thickness Gauge | Time – TT100 | 2mm ~ 200mm | 1 |

| 11 | P/Thickness Gauge | Elcometer | 0 ~ 1500μm | 2 |

| 12 | Durometer shore durometer | TECLOCK | Type “A” & Type “D” | 2 |

| 13 | Leeb Hardness tester | TIME | TIME5370 | 1 |

| 14 | Surface Roughness tester | Mitutoyo | SJ210 | 1 |

| 15 | Light meter | BENETECH – GM1010 | 0~200000 lux | 1 |

| 16 | AC Clamp meter | HIOKI | 3280-10F | 1 |

| 17 | Portable PMI Analyzer | Hitachi | X-MET 8000 | 1 |

| 18 | Helium Leak Detector | ALCATEL | ASM 142D | 1 |

| 19 | Pressure Recorder(Digital Type) | Hanyoung | 0~10MPa | 1 |

| 20 | Temperature Recorder | Hanyoung | GR100 | 1 |

| 21 | Variable area gas flowmeter | Dwyer | 500ml ~ 10000ml | 3 |

STEP 1

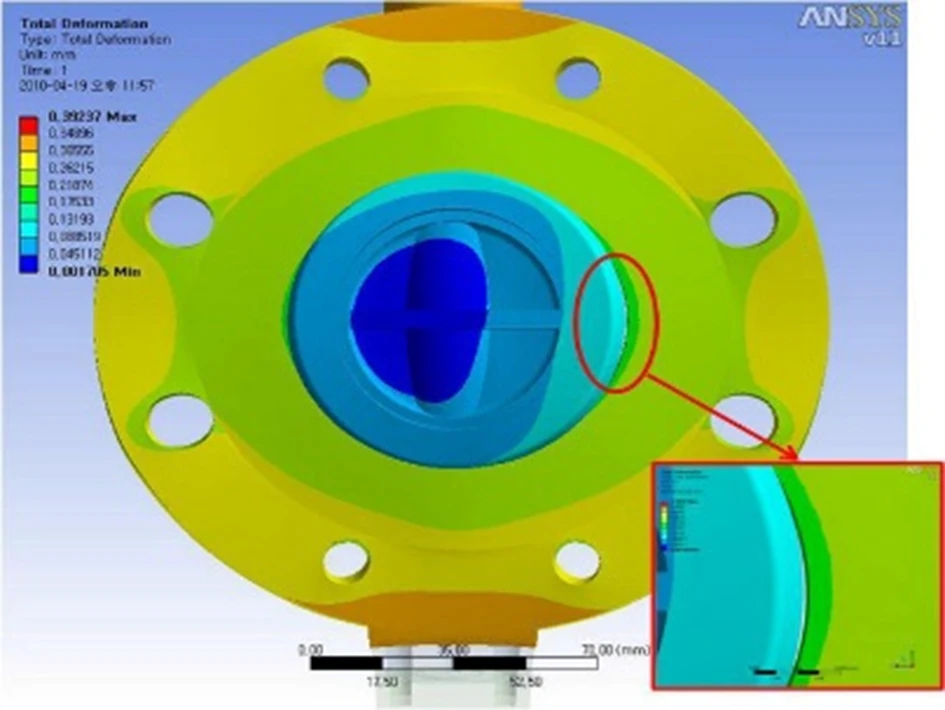

Design

▷ Spec. 검토

▷ 설계 검증

STEP 2

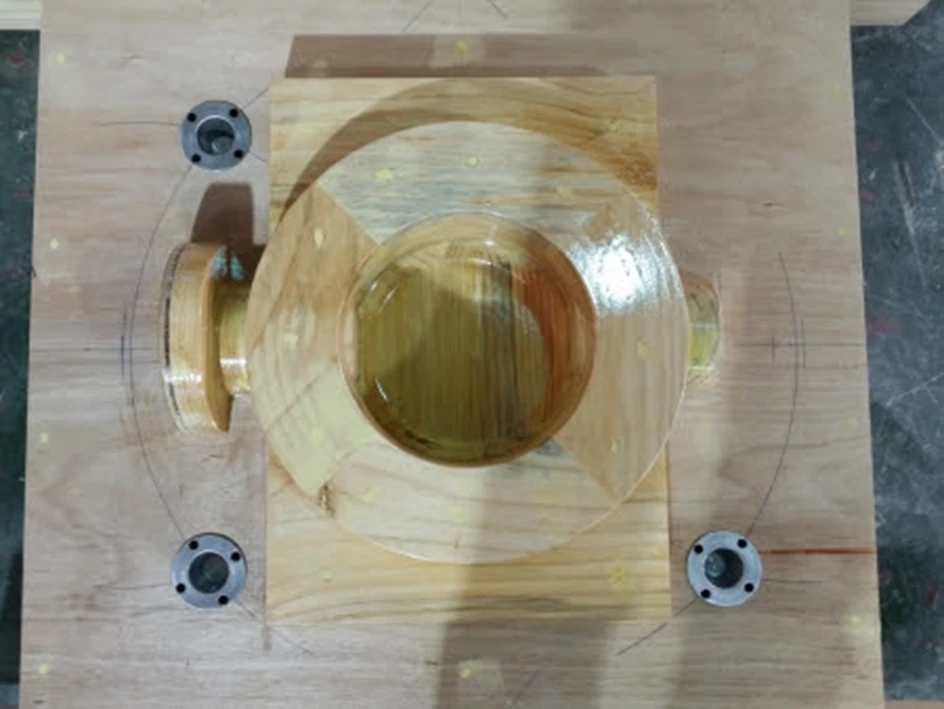

Wooden mold production

▷ 주조 방안 연계

▷ 치수 체크

STEP 3

Casting

▷ 정확한 성분 분석

▷ 가우징, 후처리 작업

STEP 4

Heat Treatment

▷ 열처리 온도 준수

▷ 열처리 후 쇼트 & 산처리

STEP 5

PMI

▷ Positive Material Identification

▷ Visual, Dimension, Marking etc.

STEP 6

Machining

▷ 작업지침서 준수

▷ 공차 관리

STEP 7

Non-Destructive Testing

▷ Magnetic particle test

▷ Liquid penetrant test

STEP 8

Assembly

▷ 조립 지침서 준수

▷ 작동 확인

STEP 9

Inspection

▷ 성능 검증

▷ 품질 확보

STEP 10

Painting

▷ Painting spec. 준수

▷ Color & D.F.T 검증

STEP 11

Packaging

▷ Packing spec. 준수

▷ 파손 방지 포장

STEP 12

Delivery

▷ 요구된 납품일에 배송